OOOPS

|

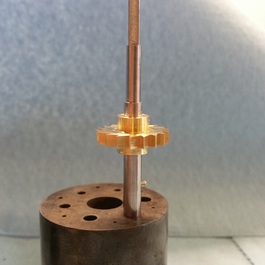

This is just after knurling the area where the ratchet wheel would press on and before I tried pressing it on. I had coated it with layout dye so I could mark where I wanted to knurl it.

This is the new arbor and ratchet wheel after I had driven the ratchet wheel to the correct location. Notice the shoulder just above the ratchet wheel. Now you will see why I felt so stupid.

|

|

Thanks to Steve Conover and Larry (caddwg) from the Clockmakers Newsletter forum for their advice when I got hung up.