Making a Junghans swinger Clock mainspring barrel

Click on any photo for a larger image.

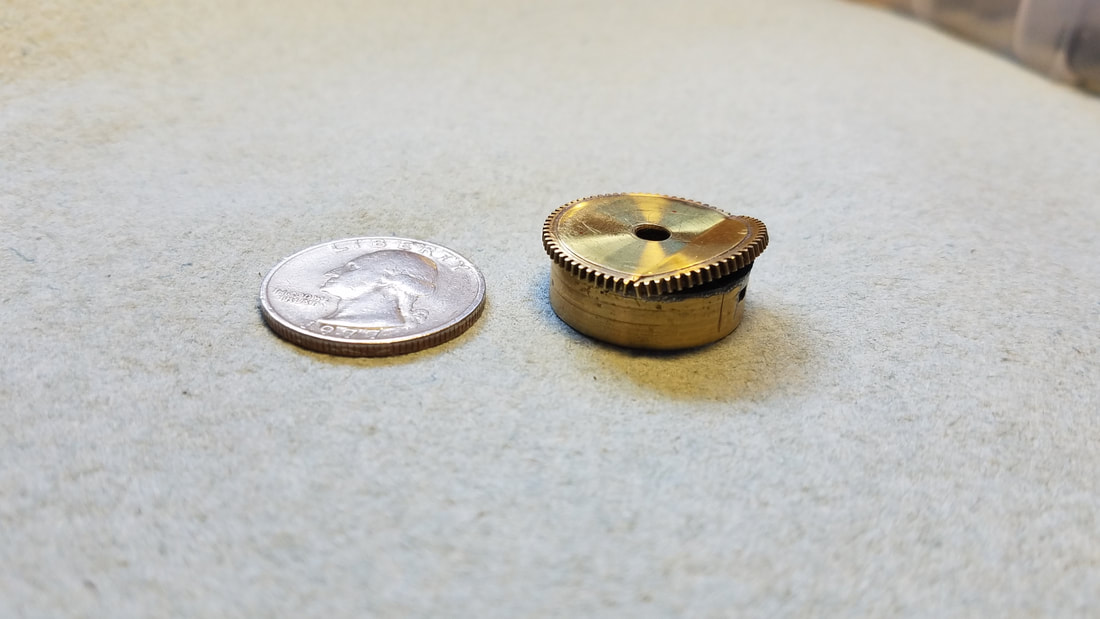

A customer recently asked me to make a new barrel for a Junghans Swinger clock. He had a mangled barrel he sent me to reproduce. The old barrel had a solder repair that had failed when the mainspring had let go and broken into 4 pieces and several teeth had been replaced. It was time for a new one. The Junghans barrel is small... less than 1 inch at the major diameter so I made the new barrel from 1" brass rod.

|

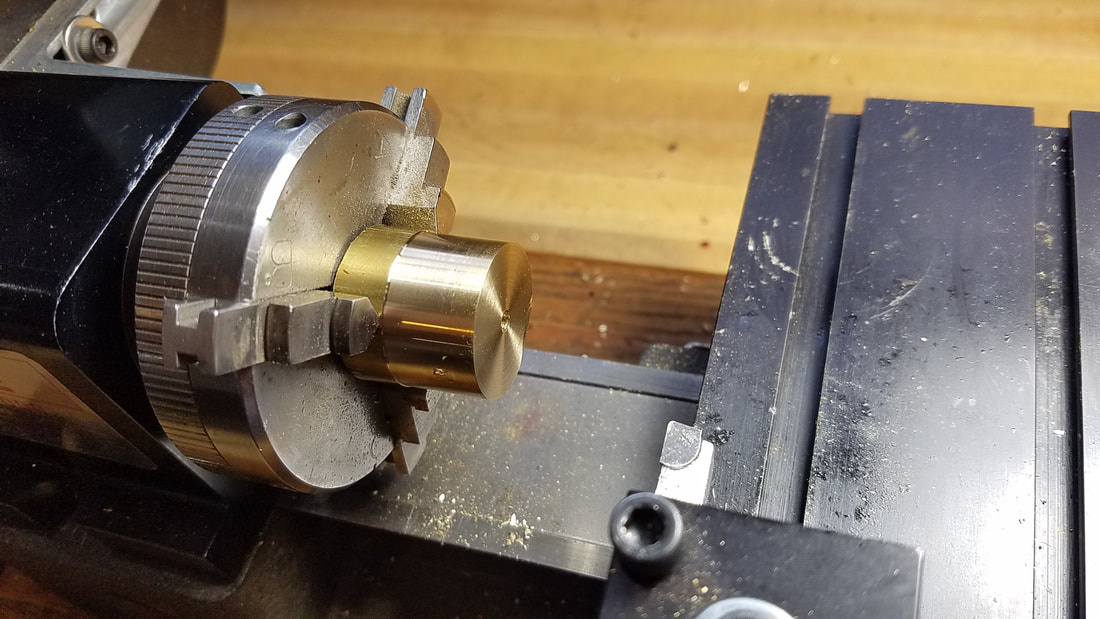

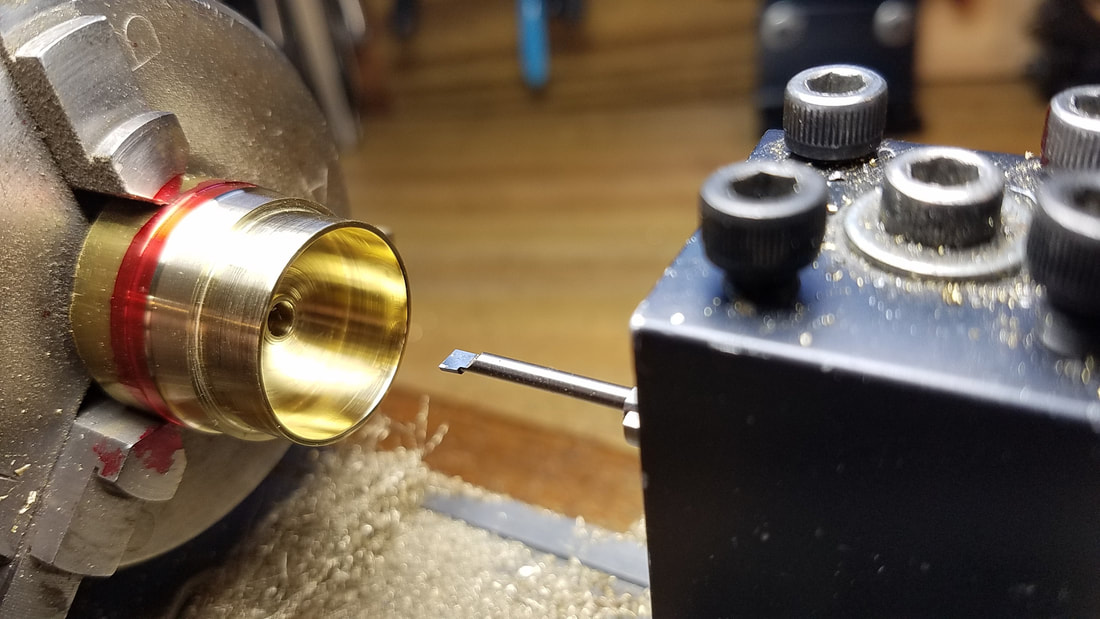

The first thing I did was to make a single point fly cutter that matched the tooth profile of the old barrel. For more details on how I made the cutter see my Repair Procedure for the Telechron Setting Gear, Page one. |

|

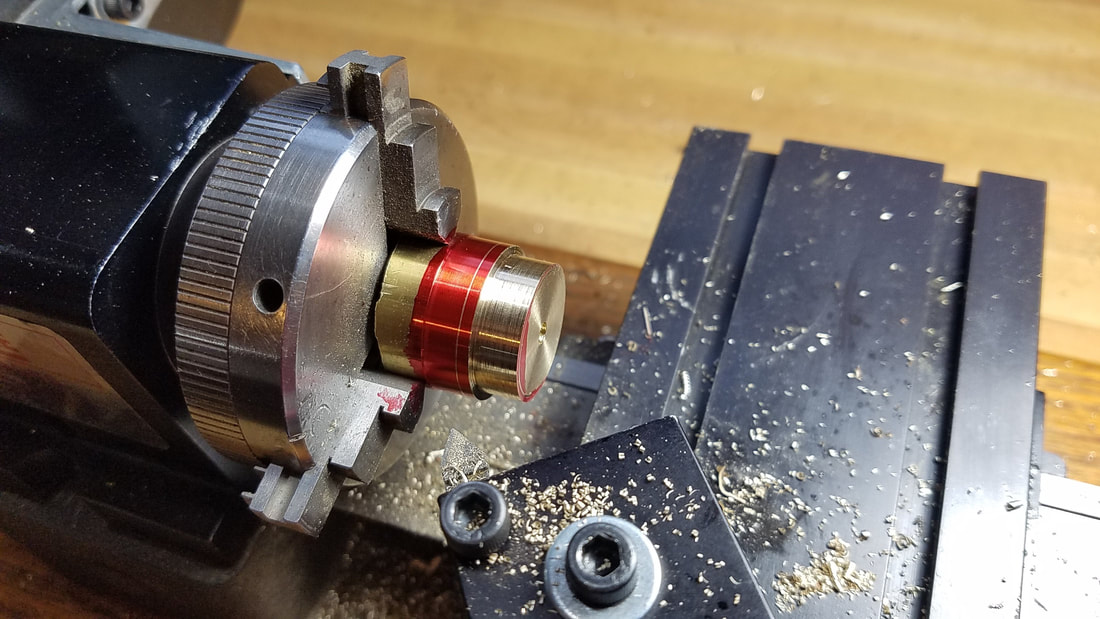

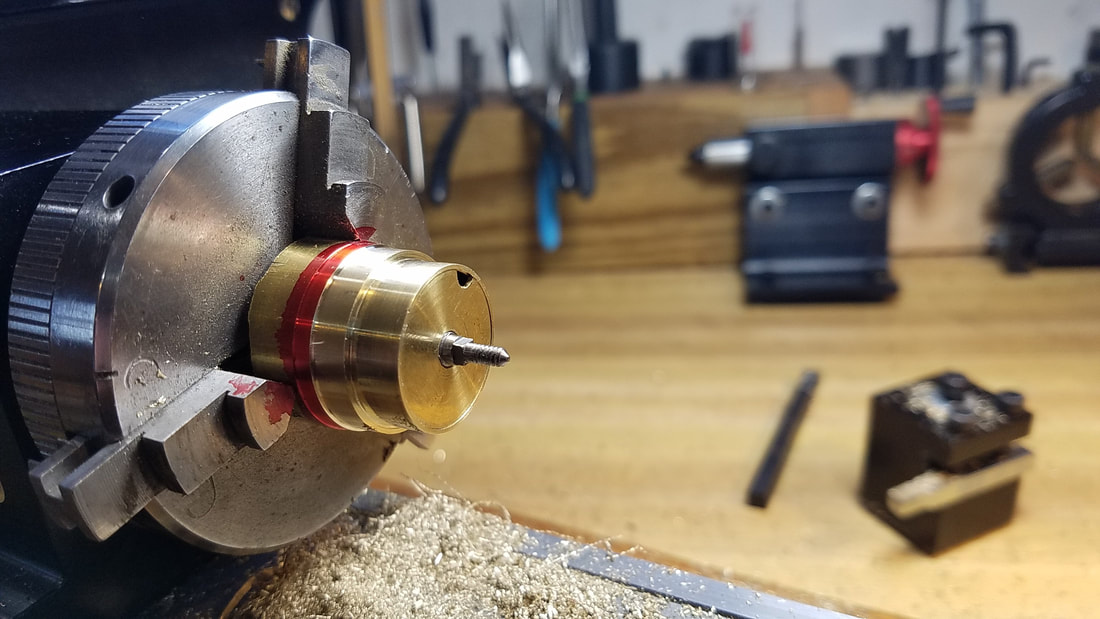

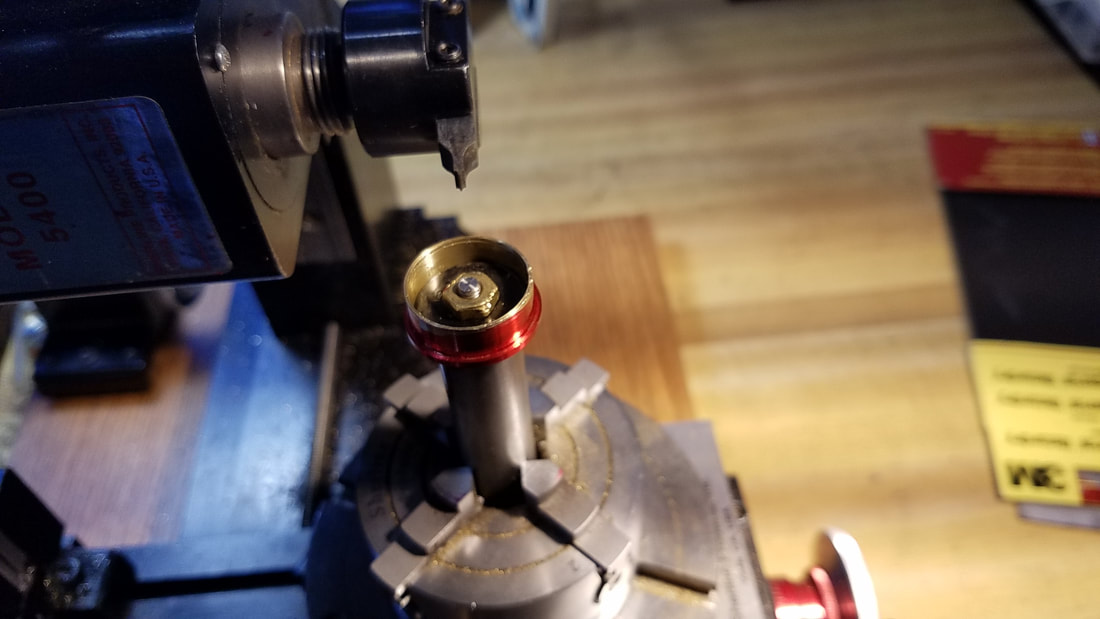

Boring the hole until I have the correct sleeve ID and depth. This was pretty slow going as the depth of the hole is actually deeper than the sleeve which leaves very little room for error on the depth. Also slowing the boring down is there is a raised bearing surface for the arbor bushing. It would have been much easier if the bottom had been entirely flat. In this situation it is critical to pay close attention to the handwheel settings and make sure you zero both axis before you start boring. |

|

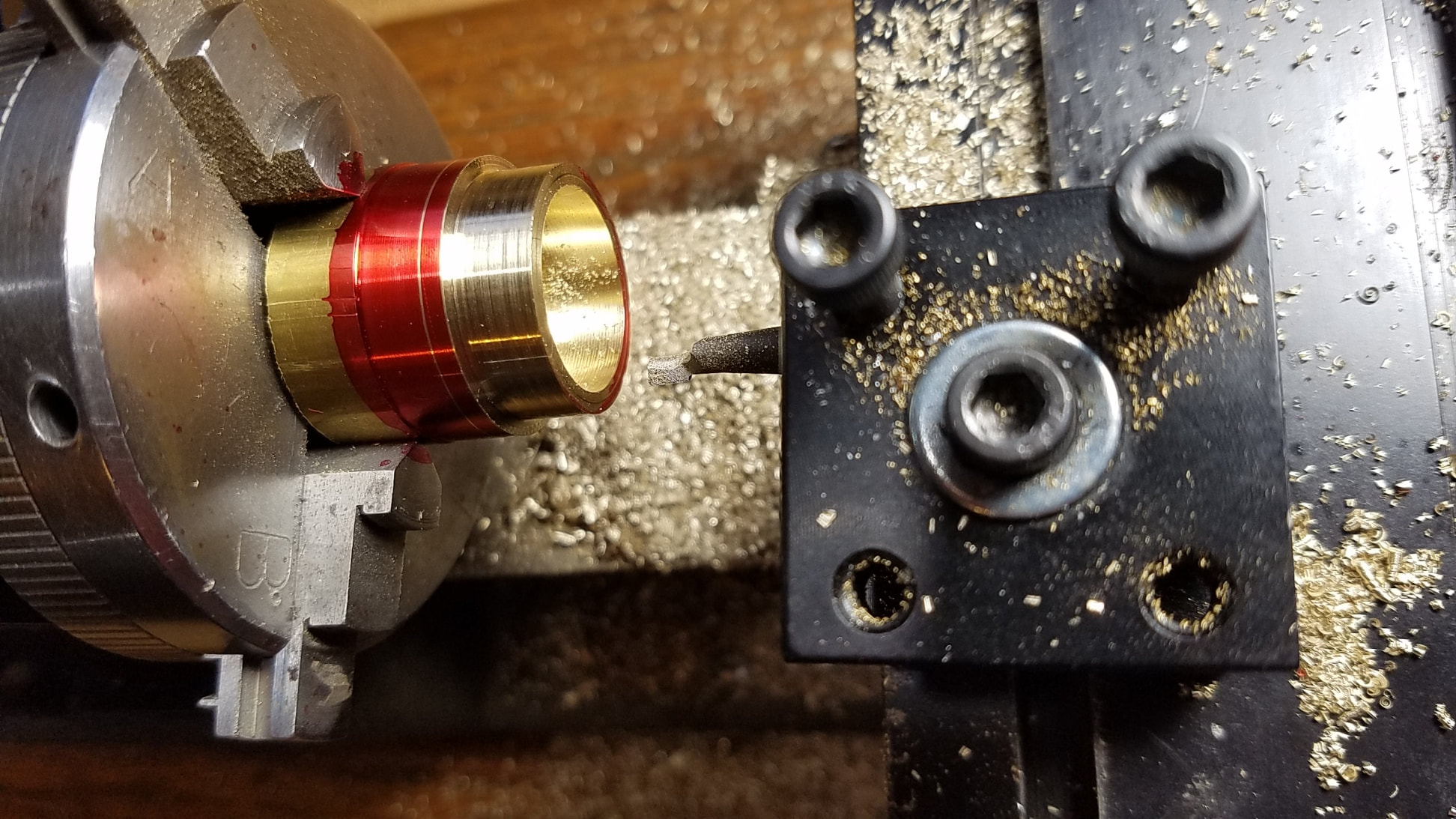

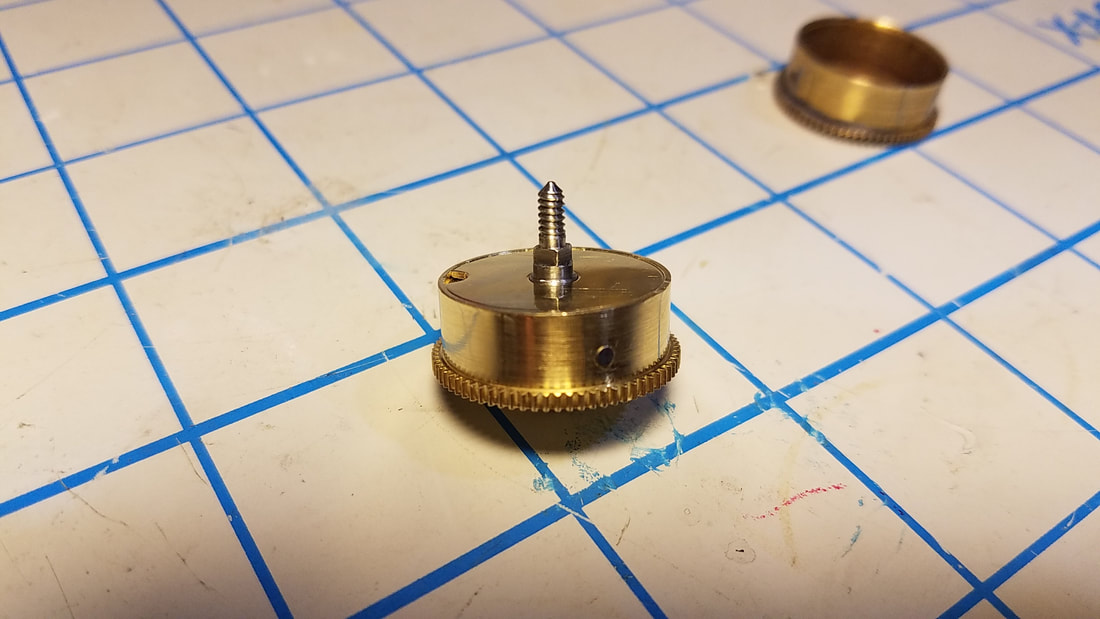

Here I have finalized the ID and if you look closely you can see the raised area around the arbor hole for additional bearing support. I also used a different boring bar to cut the groove for the cap. The groove has a slight bevel to ensure the cap pops in and stays securely in place. I also bored arbor hole to final size in this step. |

|

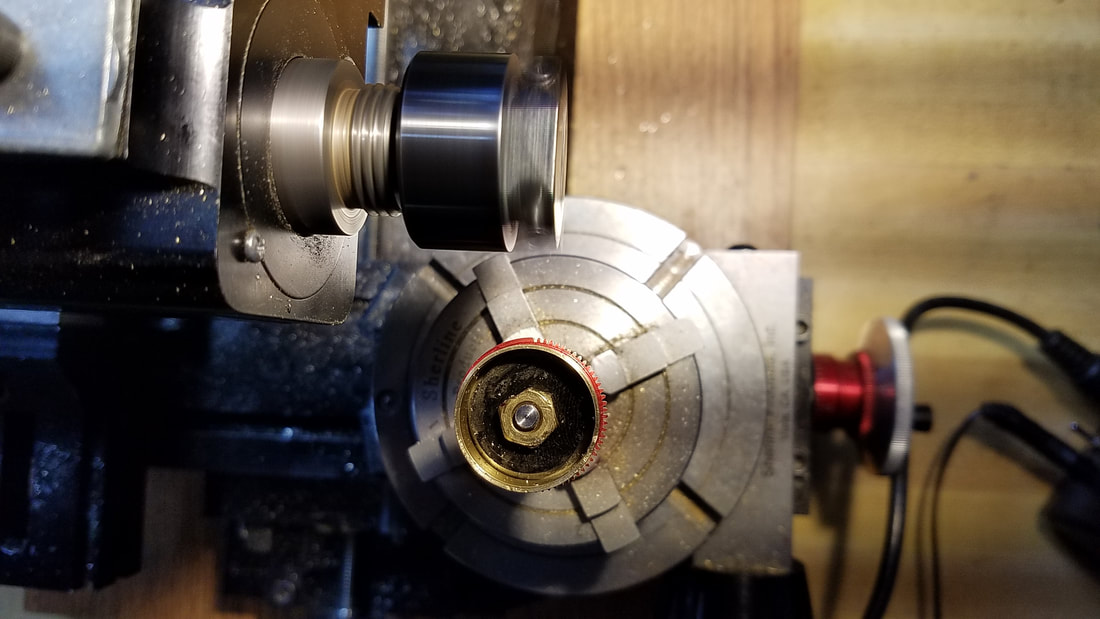

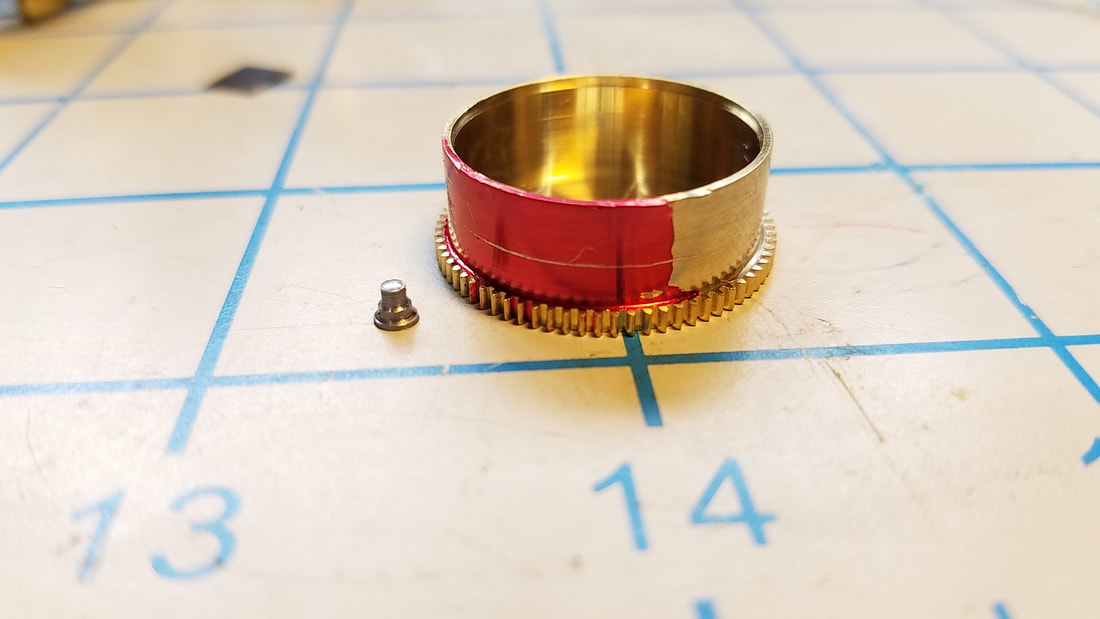

Finished cutting teeth. Marked with layout dye to locate hole for barrel hook. Notice the hook I machined sitting next to the barrel. For more info on how to machine and install a barrel hook see my Repair Procedure for Barrel Hook Replacement. |

Thanks for looking. Feel free to contact me for more details about making a clock mainspring barrel. Also contact me if you need any type of barrel machining or a complete barrel fabricated.