I recently had to replace a barrel spring hook in a 400 day clock barrel. I know this is a job that can be a little intimidating to someone that has never replaced one. I decided to take some pictures as I did this and document the steps involved so someone that has never attempted this will feel comfortable to replace a hook.

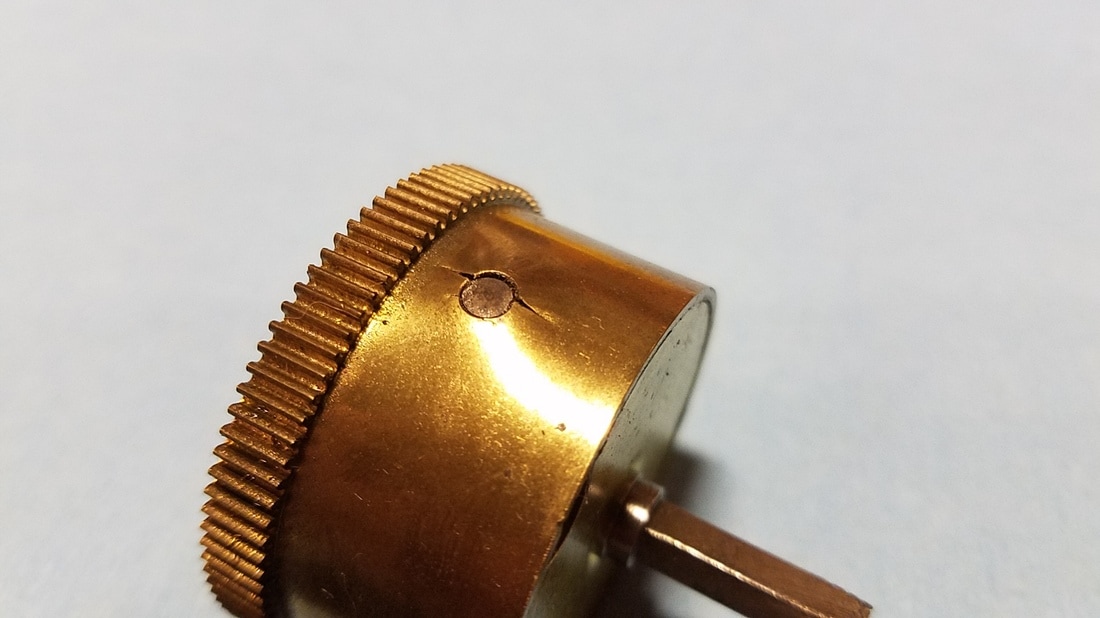

This particular barrel was in a Schatz '49' 400 day clock. Even before I disassembled the clock I had noticed the barrel had a large bulge and a small crack at the location of the barrel hook. I wasn't too terribly surprised that the hook broke completely off when I was using my spring winder to remove the spring from the barrel.

There are quite a few ways to replace a bad or missing hook and I am not saying this is the best method but it has worked well for me. I first read about this procedure in Steven Conover's Clockmakers Newsletter and have modified it somewhat to suit my equipment and material.

Click on any photo for a larger image.

Feel free to contact me if you have a question about this procedure. My info can be found on the 'Contact' page

This particular barrel was in a Schatz '49' 400 day clock. Even before I disassembled the clock I had noticed the barrel had a large bulge and a small crack at the location of the barrel hook. I wasn't too terribly surprised that the hook broke completely off when I was using my spring winder to remove the spring from the barrel.

There are quite a few ways to replace a bad or missing hook and I am not saying this is the best method but it has worked well for me. I first read about this procedure in Steven Conover's Clockmakers Newsletter and have modified it somewhat to suit my equipment and material.

Click on any photo for a larger image.

Feel free to contact me if you have a question about this procedure. My info can be found on the 'Contact' page

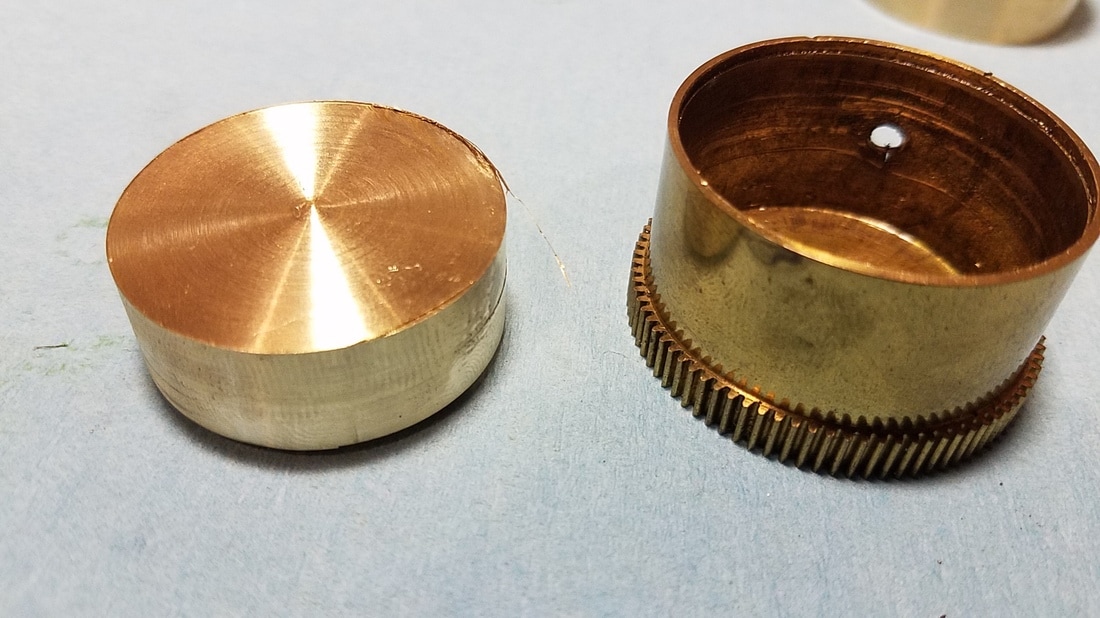

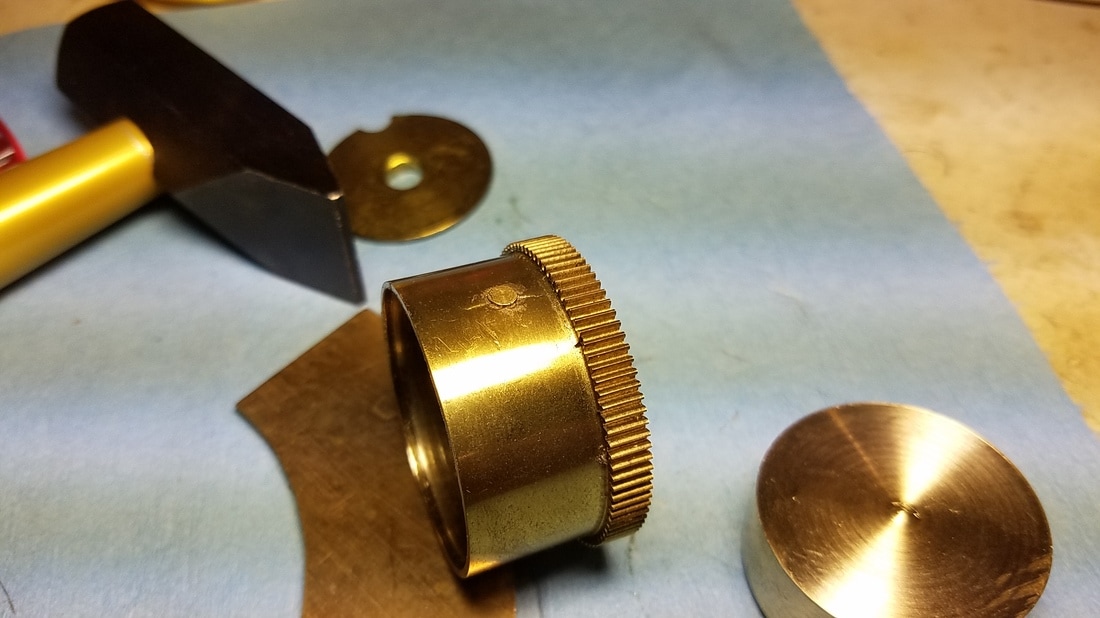

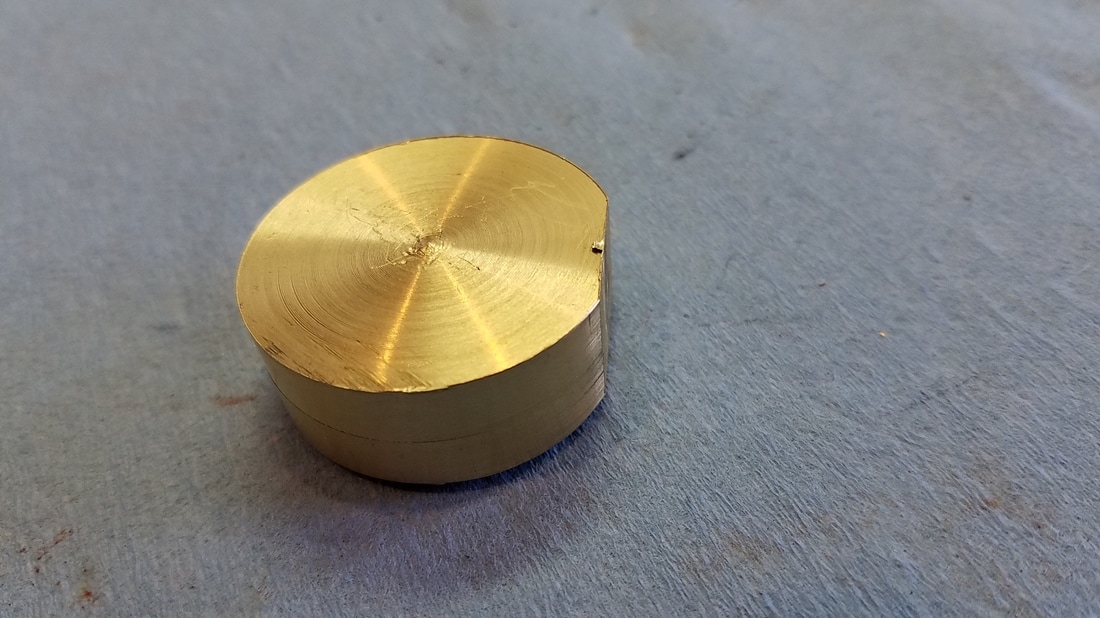

I could not use the same location for the new hook since there was a crack in the barrel so I had to reform the barrel and install a plug in the old hole. I needed to find something to slide in the barrel with nearly the same shape and size as the ID of the barrel to use as a stump or anvil so I could use a punch and a hammer to repair this. I have a variety of things I have used in the past such as some iron pipe couplings used for plumbing. This time I found a piece of scrap brass that was already nearly the perfect size so I just turned it down enough for a slip fit in the barrel. If it had been a little small I could have shimmed up the bottom so it would have been tight at the top where I needed to hammer. Also be careful when hammering to protect the barrel teeth.

|

I like to fill the hole with a bushing blank. I reamed the hole out to the next size using my bushing tool and hammered in the blank.

|

Bushing blank installed in old hole.

|

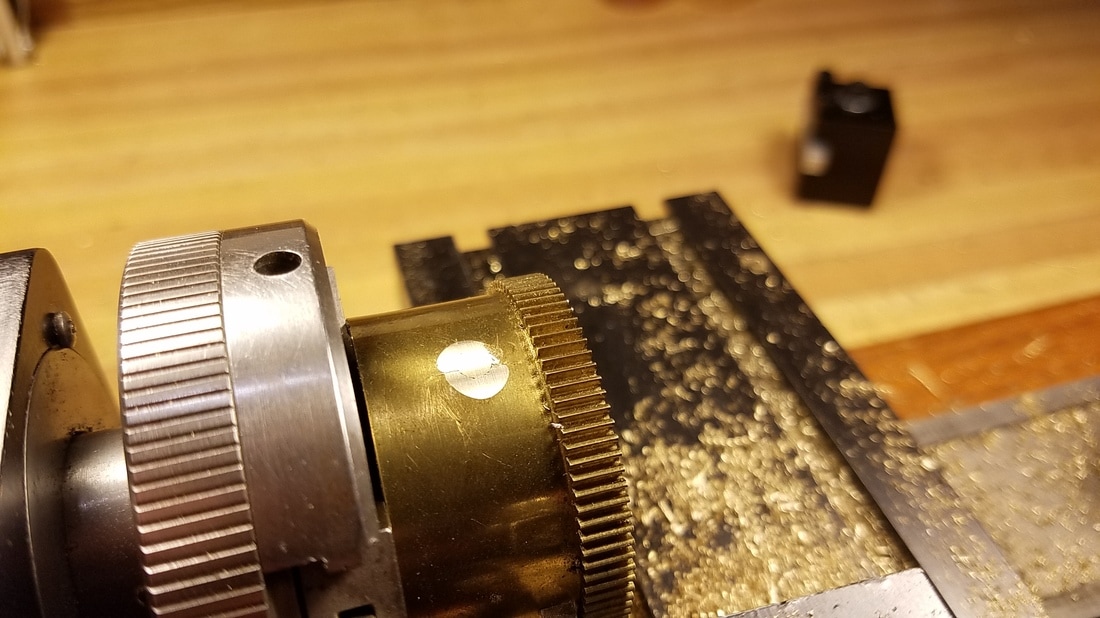

I mounted the barrel in a 3 jaw chuck and I turned down the excess blank. As you can see the repair will be almost invisible when the barrel is polished.

|

Now I needed to turn the new barrel hook. I used .1875" drill rod to make the hook. The dimensions are as follows. The rivet portion was turned to .113" diameter and .090" deep. I used .113" as the diameter of the rivet part so it would be a snug fit in a hole drilled with a #33 drill bit. The middle portion of the hook was turned to .145" diameter and .035" deep and the head was turned to .185 diameter and .025" deep.

|

This is the hook just before I parted it off.

|

Here you can see the new hook and also the old hole that has been plugged.

|

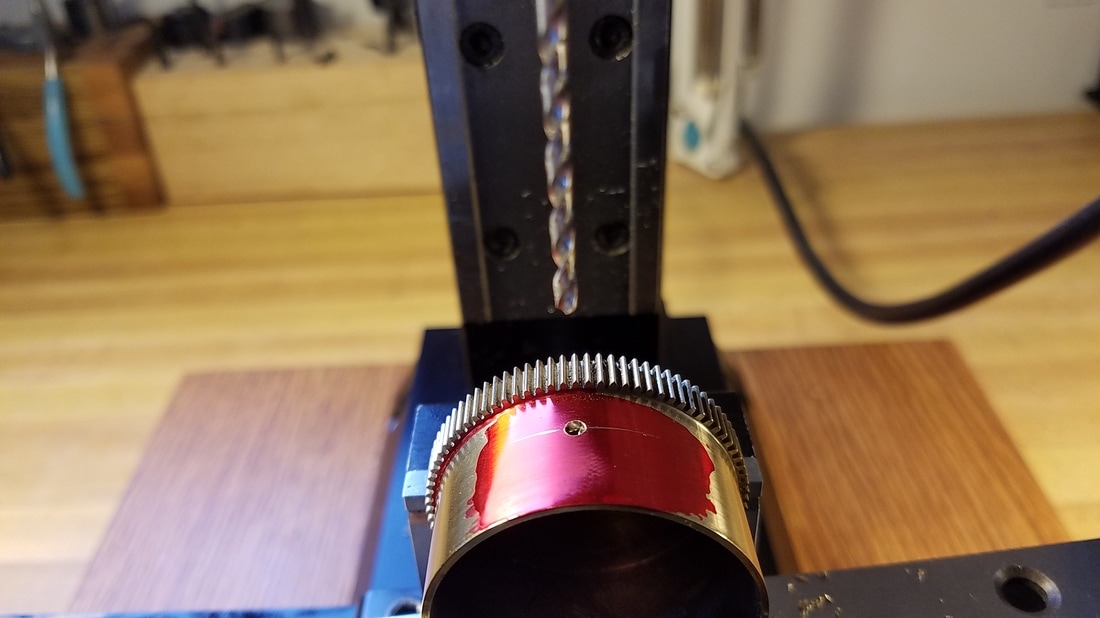

I measured the location of the old hole and transferred that location 180 degrees to the other side of the barrel. Here I have the barrel marked and have drilled the new hole with a #33 drill bit

|

|

Now I needed a way to securely back up the new hook so I could firmly stake it in place. I took the piece of brass that I had used before and milled off just enough of one edge that when put in the barrel it was snug against the head of the hook.

|

Here is the barrel hook staked in place. Unfortunately I don't have enough hands to take a picture to show how it was staked but I used a 1/4 " punch on the outside of the barrel. You need to remember to protect the barrel teeth while using the hammer. It is a very tight and secure fit.

|

After putting the barrel back in the lathe and cutting down the excess rivet that stood proud. This picture is also after using some crocus cloth to polish the barrel.

|

I want to stress there are other ways to achieve these results but I wanted to show the method that works very well for me. I didn't time how long this repair took but I am sure it can be done in 2 hours or less for anyone that is familiar with simple machine work. If you have any questions about this repair please don''t hesitate to contact me.