I recently needed to drill a hole in the top of a 400 day clock glass dome. This is more of a tool review than a repair procedure.

|

I found these hole saws online that were advertised for glass and ceramic. This set included 5/16" through 1/2" hole saws. I found them on Amazon and there were other manufacturers that had similar diamond coated hole saws.

|

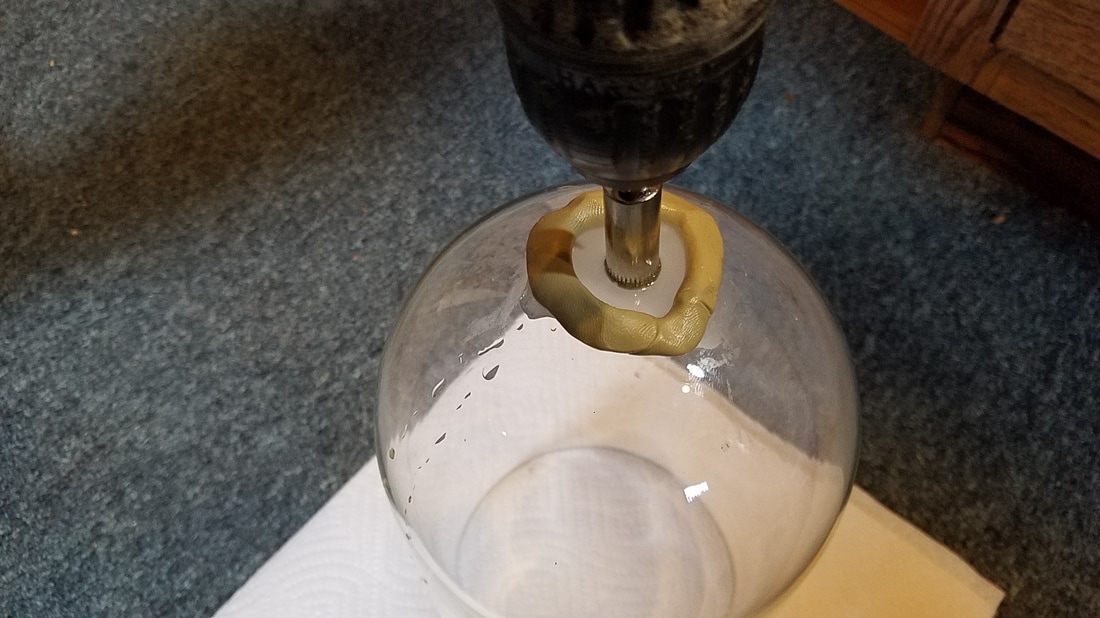

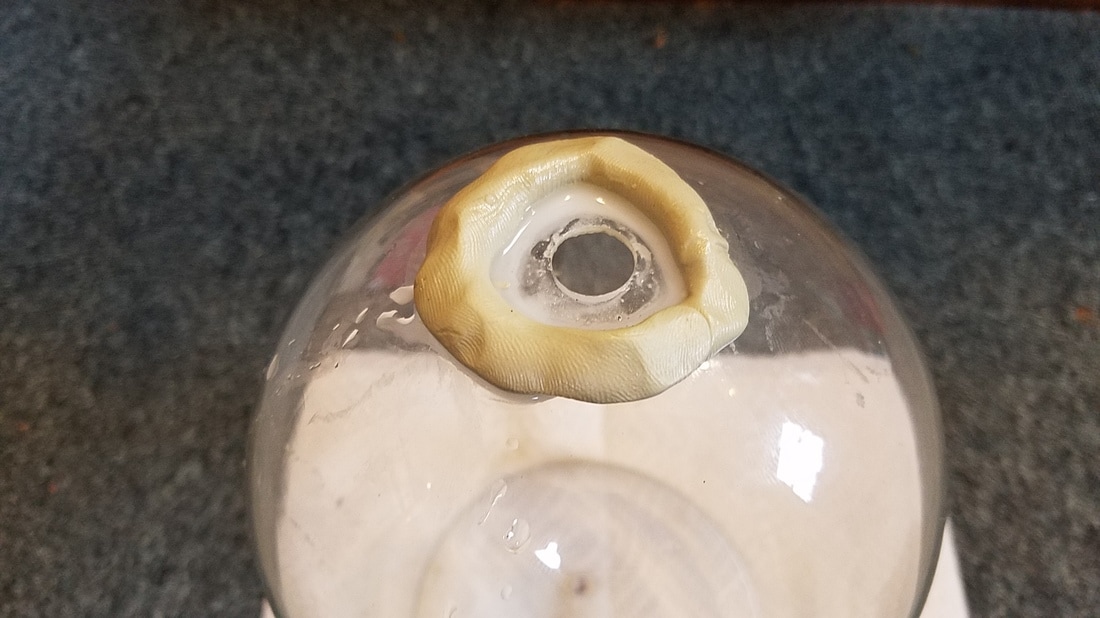

I marked the position of the hole with a sharpie. The instructions said to keep the hole saw flooded with water while drilling so I made a dam out of plumbers putty and filled it with water.

|

|

It was a very easy and simple procedure. I would highly recommend purchasing a diamond coated hole saw when the need arises to drill a hole in glass.

|

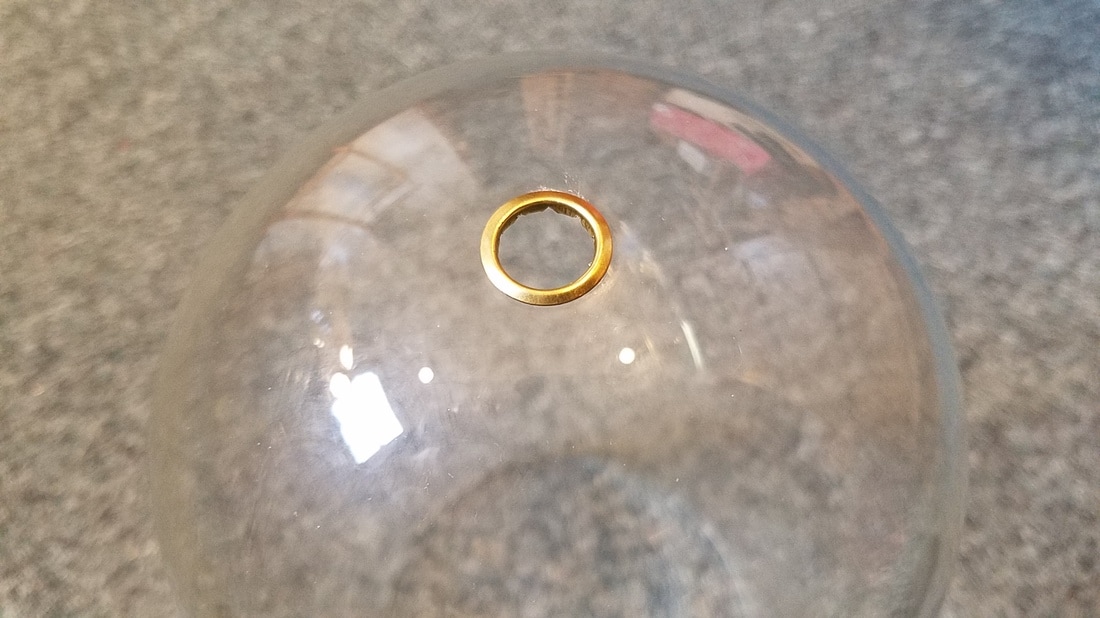

I added a grommet for a nice finished look.

|