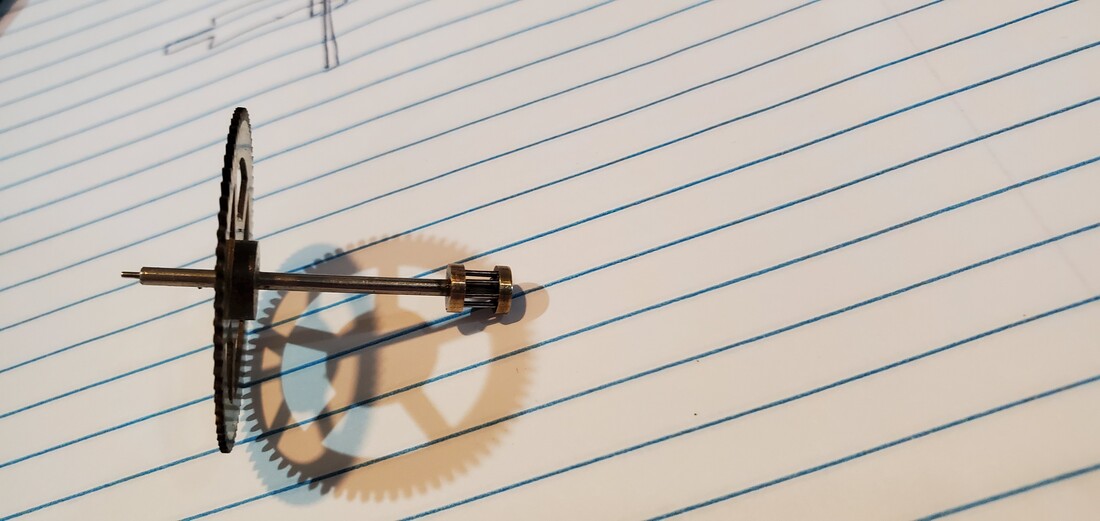

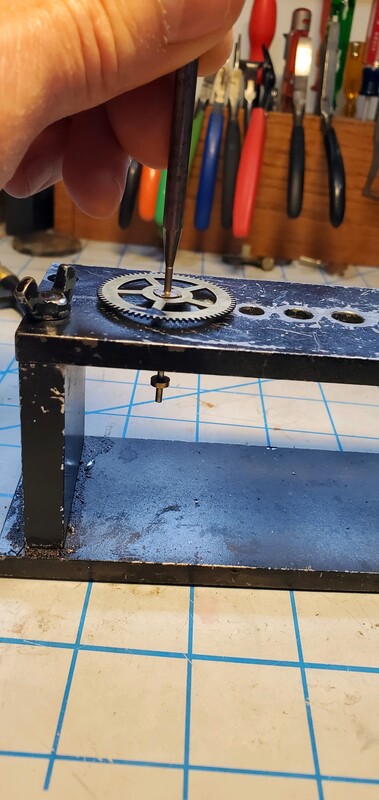

After re-pivoting dozens of arbors without too much difficulty I guess the inevitable had to happen eventually. This page will show how to recover after breaking a small drill bit off in an arbor while drilling to install a new pivot. There are many ways to still have success after a problem like this but this seemed like the best repair in this case. The arbor I was repivoting was .073" diameter and the broken pivot needed to be replaced with a .026" pivot. I had faced off the end of the arbor smooth, touched the end with a small center drill and was drilling with a #72 high quality HSS twist drill. I had cleared chips several times and was almost to the depth I wanted when it broke off flush so no chance of pulling it out.